Novel printing technique enables the production of custom porous 3D printed biomaterial scaffolds

Technology #33859

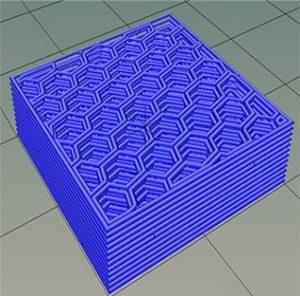

UCF researchers have developed a new 3D printing technique to produce biomaterial scaffolds with controlled porosity. This technique enables the design and production of 3D printed structures with pores throughout the scaffold, providing additional sites for seeded cells to adhere and grow.

Conventional 3D printing techniques typically generate smooth printed surfaces. Additionally, this layer-by-layer depositing method restricts the minimum resolution of printed struts to 100 µm. Thus, despite the macro-porosity between scaffold struts, such surfaces cause cells to spread into elongated spindle shapes, making it difficult to study different cellular responses. In contrast, UCF’s technique produces different 3D scaffold designs of varying pore morphology and stiffness. These features enable cells to better adhere and grow as they would in vivo, providing the opportunity to study different cellular responses and functions.

Technical Details

This invention comprises methods for producing 3D printed structures with hierarchical porosity (pores within printed features). By combining conventional extrusion-based 3D-printing with freeze casting, the technique can be used to control the pore formation of different biomaterial scaffolds for specific applications. The physical properties of the printed scaffolds can be tailored by varying parameter settings such as materials, printing patterns, and freezing temperature.

Benefits

- Enables the production of 3D-printed structures with controlled porosity

- Supports a variety of structural designs

- Low cost

Applications

- Biomaterial scaffolds for medical use

- Energy or waste remediation applications

For more information, refer to the technology sheet.