A New Way of Making the Nanoparticles Found in Common Household Products

May 5, 2016

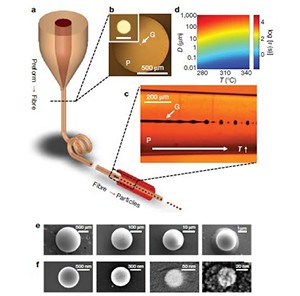

Fluid capillary instabilities in multimaterial fibres as a route to

size-tunable particle fabrication.

Ayman Abouraddy, Ph.D., associate professor in The College of Optics and Photonics (CREOL) at UCF has helped create a new way to form micro- and nanoparticles. This new way of doing things can potentially be a game changer for a variety of industries where these tiny particles are used including healthcare, health and beauty products, and industrial and residential coatings.

Because this new technique does not require a chemical reaction, the particles are safer to use in products that come in to direct contact with our bodies, including skin care and drug delivery.

Here are four of the many ways that this chemical-free process of creating tiny particles can improve products we frequently use:

- Cancer drug delivery requires nanoparticles be able to pass through the bloodstream and then be deposited only in the targeted location within the body, reducing the risk of damaging healthy tissue. With this new fabrication technique, these sophisticated drug delivery systems can use better nanoparticle-based materials, potentially further reducing tissue toxicity.

- Paint is partially comprised of light-scattering nanoparticles. When paint dries, these nanoparticles become visible. Using Abouraddy’s technique, these tiny particles can be used to create more efficient, thinner coatings. Furthermore, coatings can now have new functions (i.e. reflective, absorptive, etc.) by adjusting the paint’s optical properties.

- In sunscreen, particles absorb or reflect UV. The commonly used active chemical ingredients, such as oxybenzone and octinoxate, can be toxic – reportedly causing hormonal disruptions. With the use of this new fabrication method, sunscreens can economically choose non-toxic materials that have tunable optical properties over known toxins.

- Most cosmetics are based on micro- and nanoparticles. Recently, the Obama administration banned plastic microbeads found in cleansers because of their harmful environmental impact—specifically, because they are made of plastic, they do not dissolve. A study published in an Environment Science & Technology report stated that every day more than 8 trillion of these insoluble beads entered America’s waterways. With this new technique, microbeads can be made of more environmentally-friendly materials.

—

The science behind this method is a process called dripping-to-jetting transition. Think of running water from a faucet: when the faucet is opened, high pressure forces water out as a jet. As the faucet is closed, pressure decreases and water droplets form as inertia (the momentum of the water) and viscosity (stickiness) work against each other. With this new approach, a fiber of a selected material is heated, viscosity drops, and spheres (particles) are created.

This is a material-agnostic approach, meaning it can work on almost any material, where other processes are material-specific. It also creates separate particles that do not cluster together or clump into one mass, which is important when using them in any of the applications listed above.

Abouraddy’s particle fabrication method has the potential to disrupt a myriad of industries. To learn about licensing opportunities, contact John Miner.