Gold-black Coating: Great for UCF Knights and for Night Vision

Gold-black Coating: Great for UCF Knights and for Night Vision

Tech Blog Thursday mixes serious science with humor and easily recognizable analogies for the less-than-scientifically inclined. The purpose of this blog series is to illustrate the potential of not-yet-commercialized technology and encourage excitement about the possibilities.

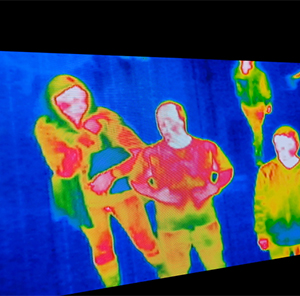

Figure 1: Thermal Image. UCF researchers developed a method of applying gold-black coating to bolometers for better production and performance, resulting in improved thermal images.

January 8, 2015

Gold.

Black.

Coatings.

To a nontechnical audience, these words might bring to mind sweatshirts and jackets available at the UCF bookstore, but a new technology available for licensing takes gold-black coating to another level. UCF researchers have developed a novel method for applying gold-black absorptive coating for use in thermal infrared (IR) sensors (also known as bolometers), which are used in space imaging and night vision.

Gold-black is a nanocrystalline deposit formed when an inert gas causes gold atoms to collide and bind with each other to form a weblike structure. This coating, when applied to the thermal sensing elements of IR array detectors (that is, many detectors arranged in rows and columns), improves the absorption of IR radiation, which translates to heat. In the case of IR array detectors used in night vision applications, the higher the percentage of IR radiation absorbed, the more a person can “see” in the dark because of the differences in the heat radiated from objects, people and the surrounding environment (see Figure 1).

The patent-pending technology at UCF, a faster and more effective method of applying absorptive gold-black coating to IR array detectors, has many benefits.

With the new application method, the absorptive coating covers more thoroughly and stays on better over time compared to previously available methods. It’s the difference between a shoddy coat, one with holes that expose your arms to cold air and made with thin thread that comes more undone with every wash, compared to a well-constructed coat that covers you well and maintains its quality over time. The new coating method prevents delamination, a process where coatings flake off like a bad paint job. For your coat or a coating, it’s important to have good coverage that lasts.

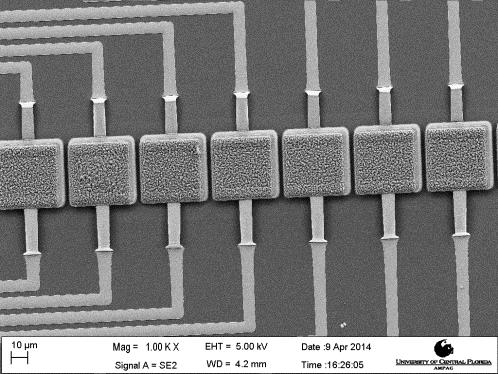

Figure 2: Gold-black patterned on sensing pixels of IR sensors to convert IR radiation into temperature change (heat).

The new method also applies the coating selectively, which saves production time and cost. By only coating the thermal sensing pixels of the IR array detectors and avoiding the non-sensing spaces in between, the time-consuming step of removing the extra material, called laser ablation, can be cut out of the production process. As a comparison, imagine if every coat was first made as a full-body suit with no holes in it for you to pull it on, see out of it or breathe well. Imagine that these coats had to have holes cut in them by hand, slowly and painstakingly. In this case, a way to easily make a coat that you could pull on and have places for your arms and neck would be in high demand.

The better gold-black coating coverage has realized at least 90 percent absorption of infrared radiation, but more often approaches 100 percent. This improved absorption results in a better IR image for applications that use this coating.

While gold-black coating is most useful for military endeavors and space-related imaging, you can sport your Knight pride by wearing gold and black coatings of a different sort.

To learn more about partnering with UCF to bring this technology to market, contact Raju Nagaiah.