Methods for Using Gold (III) Compounds to Potentially Treat Tuberculosis (TB)

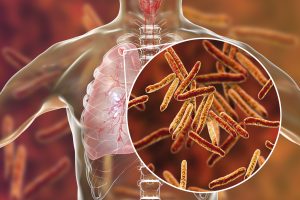

Tuberculosis (TB) is one of the top 10 causes of death worldwide, according the World Health Organization (WHO), and multidrug-resistant TB (MDR-TB) remains a public health crisis and a health security threat. TB attacks the lungs and is caused by Mycobacterium tuberculosis (Mtb), a bacteria that can also infect other parts of the body, such as the kidneys, spine and brain.

Now, researchers at UCF and the University of the Witwatersrand, Johannesburg have identified compounds that could potentially be used to treat TB and be effective against drug-resistant strains of mycobacteria. The researchers found that gold (III)-complexed compounds demonstrate antimicrobial activity against the TB bacteria. The compounds are also active against Mycobacterium abscessus (Mab), a pathogen that causes TB-like pulmonary infections, and soft-tissue and wound infections.

Infections caused by Mtb and Mab are difficult to treat and require long treatment times. Moreover, the emergence of drug-resistant Mtb strains and the high level of intrinsic resistance of Mab have increased the need for novel drug scaffolds that target both pathogens and shorten treatment times.

Benefits

- Enables the development of noncytotoxic drugs that are active against both Mtb and Mab (and other non-tuberculosis mycobacterial pathogens)

- Can be used to develop novel drugs that target bacterial topoisomerases

Applications

Treatment of tuberculosis

For more information, refer to the technology sheet.

Novel printing technique enables the production of custom porous 3D printed biomaterial scaffolds

Technology #33859

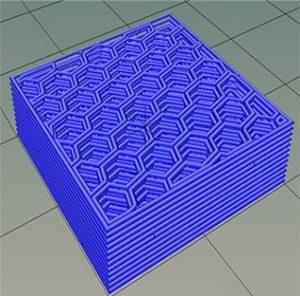

UCF researchers have developed a new 3D printing technique to produce biomaterial scaffolds with controlled porosity. This technique enables the design and production of 3D printed structures with pores throughout the scaffold, providing additional sites for seeded cells to adhere and grow.

Conventional 3D printing techniques typically generate smooth printed surfaces. Additionally, this layer-by-layer depositing method restricts the minimum resolution of printed struts to 100 µm. Thus, despite the macro-porosity between scaffold struts, such surfaces cause cells to spread into elongated spindle shapes, making it difficult to study different cellular responses. In contrast, UCF’s technique produces different 3D scaffold designs of varying pore morphology and stiffness. These features enable cells to better adhere and grow as they would in vivo, providing the opportunity to study different cellular responses and functions.

Technical Details

This invention comprises methods for producing 3D printed structures with hierarchical porosity (pores within printed features). By combining conventional extrusion-based 3D-printing with freeze casting, the technique can be used to control the pore formation of different biomaterial scaffolds for specific applications. The physical properties of the printed scaffolds can be tailored by varying parameter settings such as materials, printing patterns, and freezing temperature.

Benefits

- Enables the production of 3D-printed structures with controlled porosity

- Supports a variety of structural designs

- Low cost

Applications

- Biomaterial scaffolds for medical use

- Energy or waste remediation applications

For more information, refer to the technology sheet.

Energy Efficiency in Your Home Matters

April 26, 2018

Ever wonder what it takes to make a home or building more energy efficient or why energy efficiency even matters? Well, consider these statistics from the United States Department of Energy (DOE) and its Building Technologies Office:

Ever wonder what it takes to make a home or building more energy efficient or why energy efficiency even matters? Well, consider these statistics from the United States Department of Energy (DOE) and its Building Technologies Office:

- The U.S. spends more than $400 billion each year to power our homes and commercial buildings, consuming approximately 74 percent of all electricity used in the U.S., about 40 percent of our nation’s total energy bill.

- Much of this energy and money is wasted—over 30 percent on average.

- If we cut the energy use of U.S. buildings by 20 percent, we could save approximately $80 billion annually on energy bills and help create jobs.

Besides wasting energy and money, inefficient homes and buildings also harm the environment. Since most of our electricity comes from power plants that still burn fossil fuels, the energy that we use in our homes, offices, and facilities can be linked directly to greenhouse gas (GHG) emissions that pollute our air and water. For example, when a building’s inefficient air conditioning system must work twice as hard to keep spaces cool, it draws more electricity from the power grid than a newer, more efficient system. To keep up with the demand, the power plant must then produce more electricity by burning more fuel. That inefficiency in turn causes the plant to emit more GHGs, which can contribute to global climate change, poor air quality and acid rain.

Consider also that a typical U.S. home in 2016 consumed an annual average of 12,148 kilowatt-hours (kWh) of electricity and emitted approximately 6.67 metric tons of carbon dioxide (CO2), according to the Environmental Protection Agency (EPA). That’s equivalent to the amount of GHGs emitted when you drive a passenger car 16,353 miles or 314 miles a week for 1 year.

So when it comes to energy efficiency in homes and buildings, yes, it does indeed matter.

Building Science Research at UCF

Interior duct installed by FSEC’s home builder partner. Interior duct work results in enhanced energy efficiency, improved indoor air quality, and increased system durability.

Many variables affect a building’s energy efficiency, such as its architecture and design, the materials used to create the structure, and the kind of energy used to generate electricity. Other factors, such as heating and cooling systems and even appliances contribute to a building’s overall energy use. That’s why the UCF Florida Solar Energy Center (FSEC) has a team of research scientists dedicated to studying, testing and analyzing innovative strategies to enhance a building’s energy efficiency. Learn more about FSEC’s building science team and their ongoing local, state and national projects.

Start Saving Energy and Money

FSEC, DOE and EPA have LOTS of information to help you improve the energy efficiency of your home or business, and you can save money in the process. Here are some links to help you start saving:

- Energy-Saving Buildings is FSEC’s guide to cost-effectively reducing energy expenses in Florida.

- Energy Saver is the DOE’s consumer resource on saving energy and using renewable energy technologies at home. Check out their Energy Saver Guide.

- ENERGY STAR is an EPA-backed voluntary labeling program for helping consumers and businesses buy energy-efficient, money-saving products, including appliances, heating and cooling systems, and new homes.

Meet an FSEC Building Scientist and Inventor

Danny Parker with the Anywhere Fan blade.

Principal Research Scientist Danny Parker has been studying how houses use (and waste) energy for the past 30 years. Through is work, Parker has invented numerous technologies that improve a home’s environment and energy efficiency. To learn about Parker and his work, read this month’s Faculty Feature.

One of Parker’s most recent inventions is a portable, lightweight, PV-powered fan that quickly and easily sets up anywhere. Originally designed to ventilate homes, the invention works wherever personal cooling is needed—from outdoor events to disaster recovery areas.